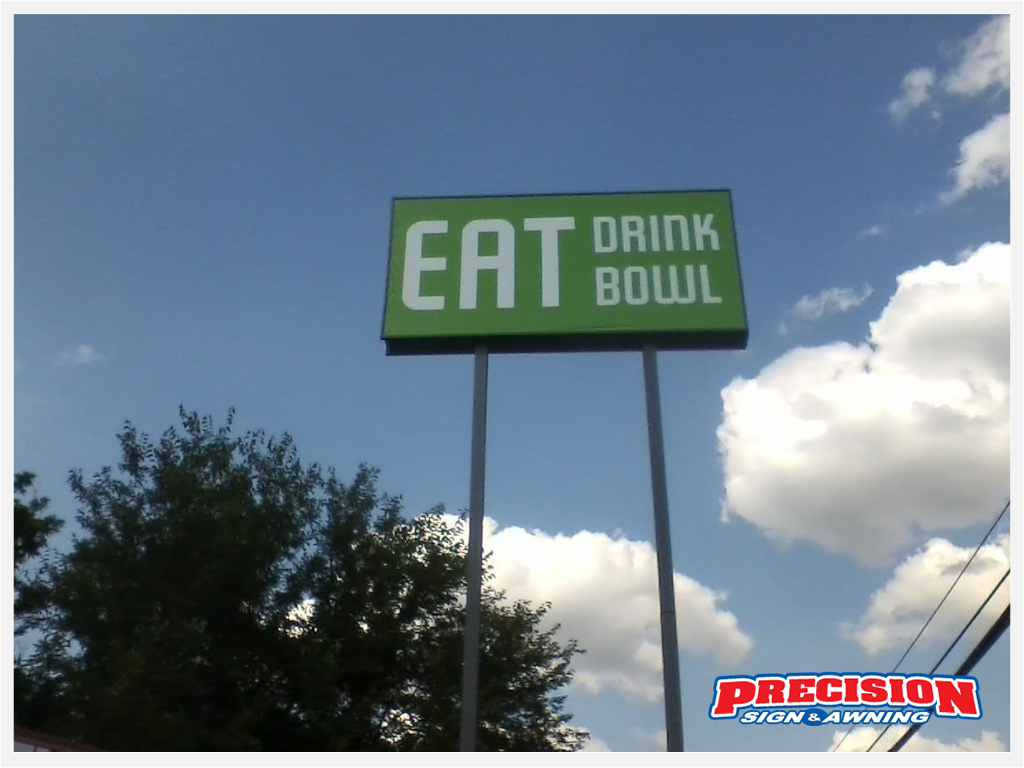

Top Quality Cabinet Signs

Cabinet Signs are the most common type of illuminated (electrical) business signs. They are usually less expensive than comparable Channel Letter Signs, but they can still be an excellent way for a Customer to have stunning, vibrant signage at a more economical price.

Assuming building codes do not dictate a particular type of electrical sign, it often comes down to whether the Customer prefers the individual letters of Channel letter Style Signage or the Sign Cabinet Style which usually allows for more detailed multi-colored designs and a more detailed text or message.

Sign Cabinets are usually much easier to install than Channel Letter Signs; although Channel Letter Signs on Raceways are comparable with ease of installation.

Cabinet Signs usually include an aluminum extrusion (sign cabinet) with an acrylic face; although many other types of faces are available. These signs can be designed and manufactured in a variety of different ways to give your business a unique and visually appealing sign.

Our Sales Associates and Designers are very skilled in helping you choose the best type of extrusion (sign cabinet), sign face, and lighting combination to best produce the effect that you desire.

Contact Melissa

Owner & President

Cabinet Sign Design & Fabrication

When you task Precision Sign & Awning with manufacturing your Cabinet Signs, you will be included in the entire process. All of our signs are manufactured at our in-house manufacturing facility in Carnegie, PA.

Design

As a full-service sign company, Precision Sign & Awning has a knowledgeable, talented and experienced design team that can take your project from concept to a full design.

If you project requires our design team, your sales representative will work directly with you and our design team to you receive the perfect design for your project.

Fabrication

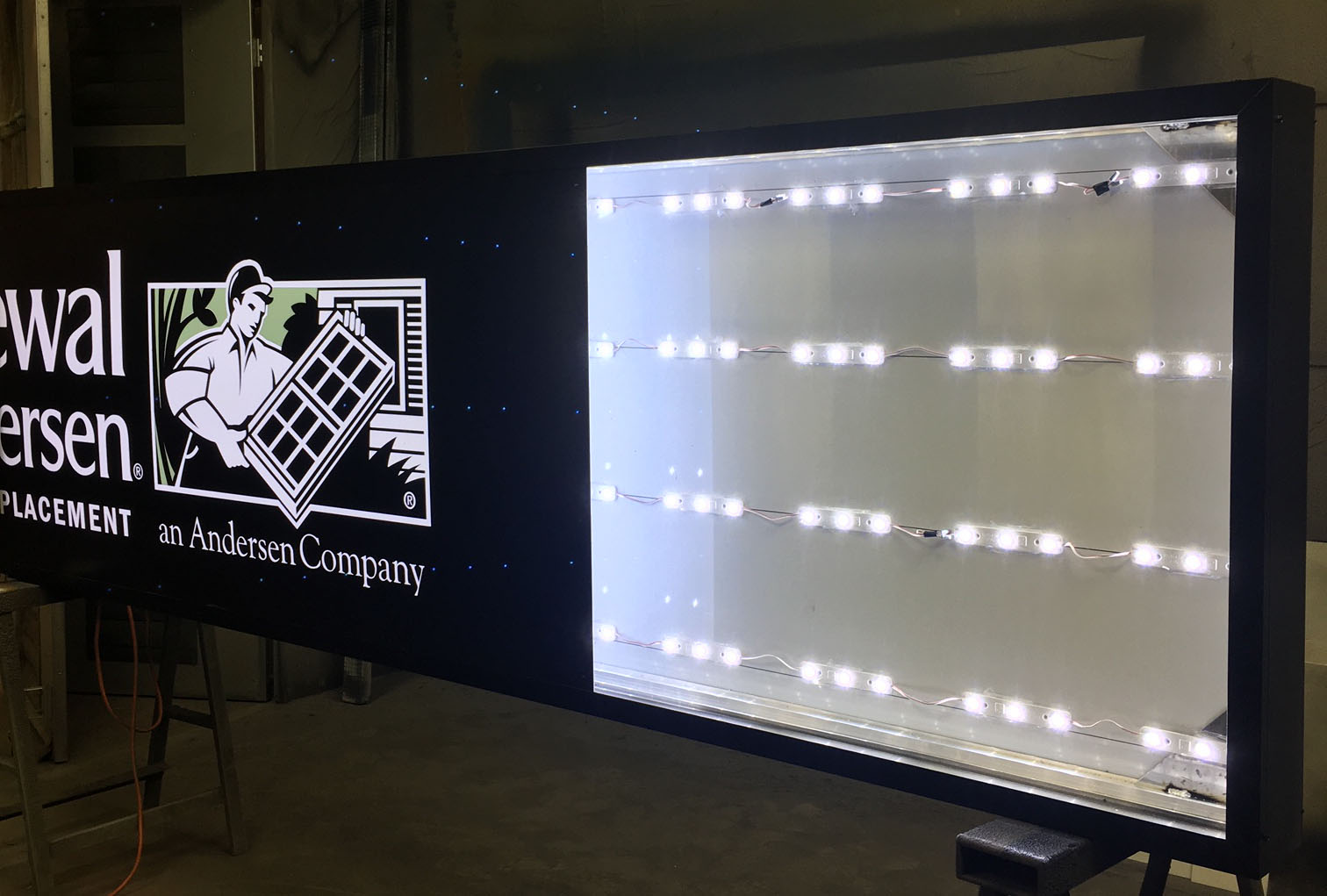

Once you have approved every aspect of the design, we send the project to our in-house team of aluminum fabricators and welders.

We often require the use of our CNC router and our hydraulic shear to create the various parts for your cabinet from raw materials.

Once the parts are created, our skilled fabricators will manufacture the sign cabinet to your exact specifications.

Painting & Wiring

After fabrication, most sign cabinets require painting and wiring for lights.

Our paint team uses Mathews Paint System to match any conceivable color and uses our state-of-the-art climate-controlled paint booth to finish the aluminum with a beautiful, long lasting paint. Matthews is a catalyst (2 part similar to epoxy) paint and has the longest life in the industry.

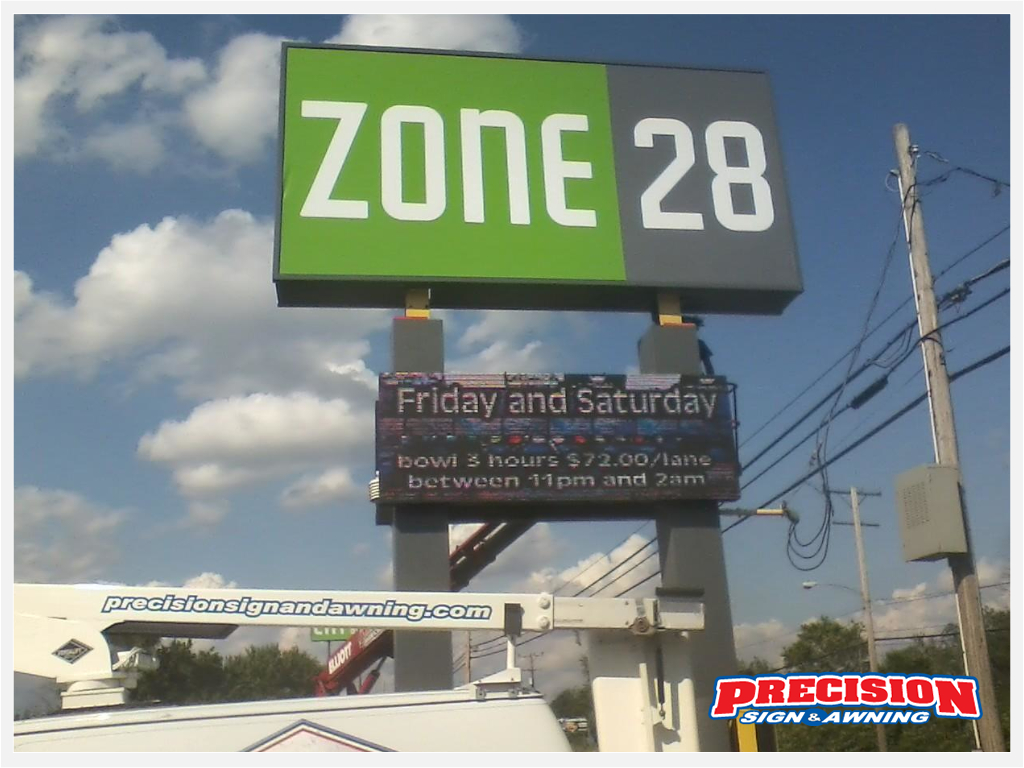

Next, the cabinet is wired with the newest technology LED lighting. LED’s are brighter, longer lasting, and less expensive than the old florescent lights. Often times, the savings is dramatic enough to warrant retrofitting current signage from Florescent to LED lights.

Cabinet Sign Face Types

While the most frequently chosen sign face is acrylic, depending on the cabinet size and your desires, we can produce a variety of different types of cabinet sign faces.

If you don’t know what kind of cabinet sign is right for your or your business, take a look below or contact us to speak with one of our experts.

We have the flexibility to produce the following types of cabinet signs:

Color-White-Color Reverse Print Acrylic Face

Recent technology has solved the age-old problem of a backlit sign looking fantastic when illuminated at night but looking slightly washed out in the daylight.

For many years, the sign industry struggled with the problem until a new technology called Color-White-Color three pass printing was invented. The more advanced large format UV printers have this technology.

All three of our large and grand format printers use Color-White-Color technology for day/night sign faces. Like the name suggests, the technology prints a layer of your design, then a white layer, and then your design a 2nd time. This produces a sign face that is stunning and vibrant when backlit at night or front lit during the day.

By printing Color-White-Color in reverse on a clear acrylic face, it creates your sign face on the back side of the acrylic. So when your face is placed in the extrusion (sign cabinet), it has the acrylic itself in direct contact with the weather, sun, and wind. The sign face is printed on the side of the acrylic that is inside the sign cabinet.

This gives your sign the best protection from the elements and ensures the longest life possible.

Translucent Pressure Sensitive Vinyl Face

Pressure sensitive translucent vinyl is used in many sign face applications. The design is cut from a single color of vinyl sheeting with our vinyl plotter.

There limitless styles and colors of vinyl to choose from and depending on your chosen design this method may be the best option for your application. Sometimes, this method has limits when printing multiple color designs.

However, we can print full-color designs on clear vinyl with our UV Printers and adhere the design to your sign face. In those applications, the prints mount on the outside of the sign face and they are in direct contact with the weather elements, but they are designed to have long-term durability even though they are in direct contact with the weather. Prior to Color-White-Color technology, this was the best method, but now it really depends on your specific design as to what will be the best option for your sign face.

Pan Formed Face

Pan formed Faces are made of acrylic but instead of the acrylic sheet being flat the sheet is heated to the point where it is pliable and then the edges are bent to allow the entire face to protrude out approximately two inches from the sign cabinet itself. Besides for the edges being bent 90 degrees, the rest of the sign surface is flat.

This sign face is usually used for larger signs because this face can withstand higher wind loads due to the bent edge design.

The drawback with this type of sign face is that it is not possible to manufacture the signs on our flatbed printers, so we are unable to print Color-White-Color faces. The advances in Flex Face Signage makes it a more logical choice for most oversized sign faces.

Embossed Face

Like pan formed faces, embossed faces require a thermoforming process.

The difference is that instead of just bending the edges of the acrylic sheet, the acrylic is also bent around lettering or designs that were previously cut out separately with our CNC Router to be used as molds for the thermoforming. So, the edges, the lettering and the designs all protrude from the face of the sign cabinet.

This method has been very popular in the past, but it is difficult to make multi-colored designs using this method. It is possible; but it is more economical to produce intricate and multi-colored designs with the more advanced technology that now exists.

The primary purpose for both the pan formed and embossed sign faces has been to strengthen the faces for maximum wind resistance making them great choices for oversized sign faces in the past. Since the aesthetic reasons to have a protruding sign face is usually lost when viewing the sign face from any distance, the advances in Flex Face Signage has made it a better choice in most of these applications.

Flex Face Signs

Flex Face Sign Faces are made with a unique banner type of flexible material called PanaFlex manufactured by 3M. The material is extremely durable and is specially treated to allow long-term durability, unusual wind resistance, and great UV (Sun) resistance.

The material is made to be backlit for illuminated sign face applications and looks equally stunning during daylight front lit applications.

Our equipment can print 10 foot wide rolls, so it can be used to make a sign face 10 foot wide by any length without a seam, and we can create faces up to 22 foot wide by any length using our state of the art Miller Hot Air Welding System. This is a big advantage over acrylic which seldom comes larger than a 5-foot by 10-foot sheet.

These signs are most commonly used with very large cabinets; usually above 5-foot x 10-foot.

Benefits over Acrylic Faces:

- Allows for a large face with no seams

- Absorbs very high wind speeds because the face has the flexibility to sway in extremely high winds

- Weigh less making installation easier and less expensive

- Less expensive than a comparable sized acrylic face

Stencil Cut Face

These faces are not as common, but they have some very exciting applications. We can cut any design in reverse from aluminum using our CNC Router.

The aluminum sheet, with your reverse design, is then placed in the sign cabinet as your sign face and acrylic is then mounted on the inside of the aluminum sheet which allows your design and lettering to show thru during day and night applications. When the sign is illuminated at night, the light shines thru the acrylic and looks fantastic.

The color contrast between the aluminum sheet color and your acrylic color makes your design stand out during the day as well.

Push thru Acrylic Letters

These sign faces are similar to the stencil cut faces but the acrylic backs are specially cut on our router to allow the acrylic to protrude thru the reverse cut metal face so the letters actually stand off from the flat aluminum background.

They actually look like small channel letters mounted on a sign cabinet. It is a unique method of producing sign faces and can give Customers’ endless options to uniquely brand their business.

Sign Installation

Once your cabinet sign is fully manufactured, wired and painted, our professional team of experienced installers will install your cabinet sign in a safe and professional manner using equipment that is properly inspected and insured. Customers’ should not hesitate to ask the sign company installing their signage to provide a certificate of insurance showing that their equipment and employees are fully insured.

Our installers are well trained and experienced in all aspects of sign installations and we have well maintained cranes and bucket trucks with the ability to lift any sign into position. Our installers are also experienced with footer and concrete installations of large architectural signs.

We will not subcontract your installation to another company. Our team takes great pride in creating your project from the design phase until final installation. It truly is exciting for us to take our customers’ vision and turn it in to a beautiful functioning sign to highlight their business and allow them to successfully develop their brand.

Industry Leading 3-Year Warranty

When you purchase your Signs from Precision, you will receive an Industry Leading 3-Year Warranty on PARTS and LABOR.

We manufacture a high-quality product at a competitive price and we are happy to stand behind it with this excellent warranty.

No customer should have to pay good money for a sign and be concerned that it might fail after a year.

The Precision Sign & Awning Difference

We have been in business since 1988. Many of our employees have been with us over 20 years, including two of our designers that have been with us since the beginning. Our wealth of knowledge, experience and talented employees give us the ability to create the perfect sign for your unique application.

To ensure we provide you with a top-quality sign from design to installation, we never subcontract any of the process and maintain full responsible for meeting any agreed upon deadlines.

When we work your project from start to finish is what sets us apart, we control the full production and installation process and we take full responsibility for every part of it. If there is ever any problem, there will not be an argument whether the wholesale manufacture, the retail sign company, or the installation subcontractor dropped the ball. Precision Sign & Awning will be responsible, and we will make it right.

We invite all our Customers to visit our manufacturing facility in Carnegie while their project is being produced so they can observe firsthand the materials being used for their project. We are proud of our workforce and our production process and we are always excited to show a Customer how their job is progressing.

Contact Melissa

Owner & President

Get A Quote

(No hard sale tactics and No obligation)

Do you have a question about your project? Please contact us for our advice, opinion, or a quote.